product design & development

We offer a wide variety of services in the field of industrial product design. The services we offer are not only for executing whole projects from A to Z. We also offer individual design plans with which we can help you with the specific issues. With these plans we make it possible to approach the projects from different angles at the same time while staying flexible and focused on the important features.

design & market research

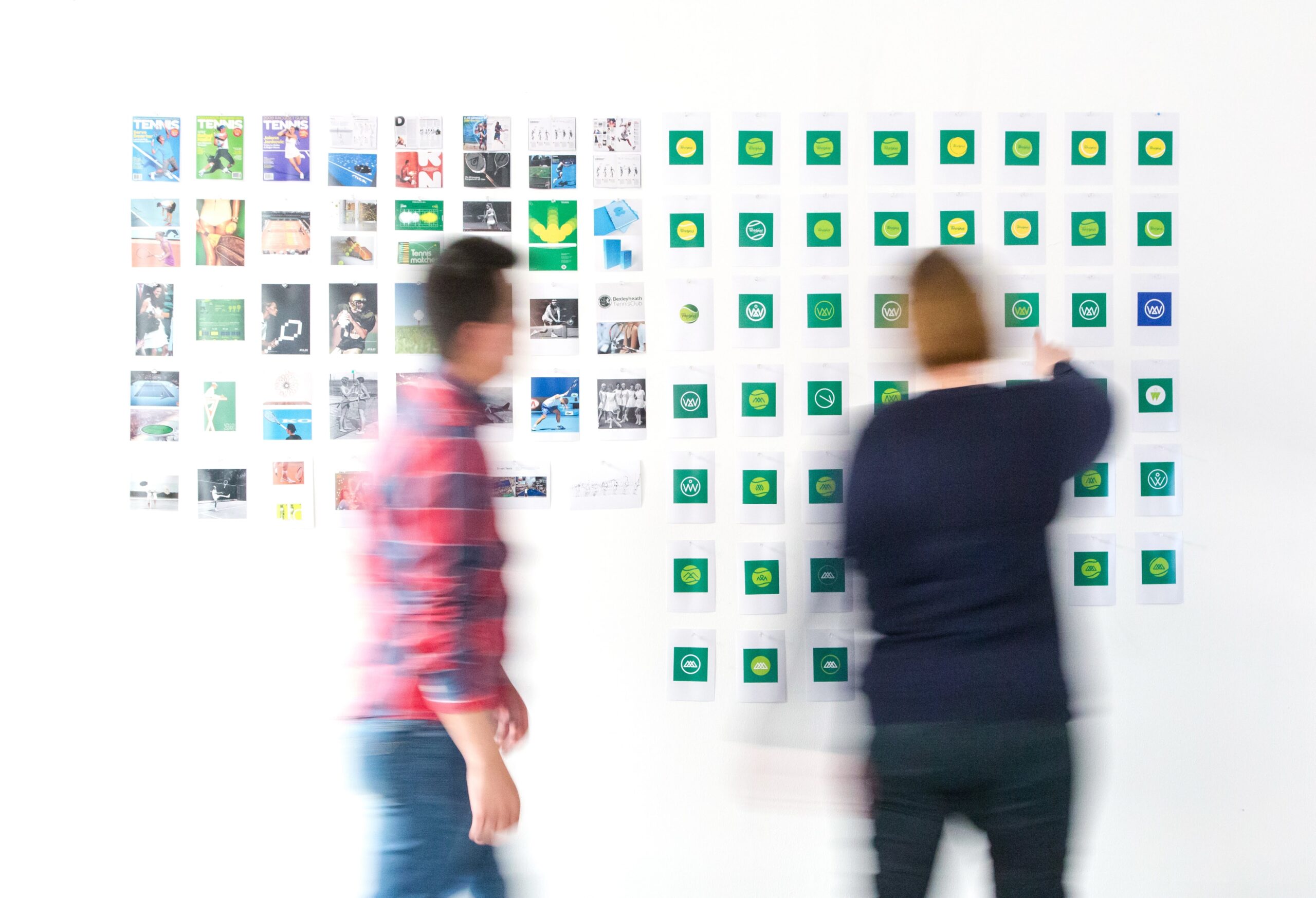

The starting point of product design and development is essential. If the starting point is not clear, the result often ultimately does not meet the design criteria. That is why it is important to map out the target group and competition during the research phase.

During design and market research phase we make a target group description and a target group collage, we also research the possibilities in your market and draw up a competitor analysis. This way the properties of future product will be mapped out.

ideation & creative concepting

Idea generation involves the creation of new ideas that provide initial insight in the direction of the final concept. These ideas are generated through brainstorming sessions.

Idea generation does not guarantee that the first idea will be worked out, but provides a good overview of almost all possible solution directions that are mapped out. This ultimately saves the client time, money and disappointment.

The client determines which ideas are developed into concepts. One or more ideas that are chosen in consultation with the client will be developed into concepts. The concepts can be represented as a real prototype, 3D models and technical drawings drawings.

product design

A successful product design is a result of creativity, talent and tenacity. We believe in designs that are attractive to the market and are clear in function and use.

In this phase we work extensively on the design of your product. We ensure that integral product design and development is guided in the right direction in order to clearly map out aspects such as ergonomics, functionality, design, costs and the choices of color and materials. In addition, we also make an extensive data and image collection about the future design and implement this in the DNA of the customer’s brand.

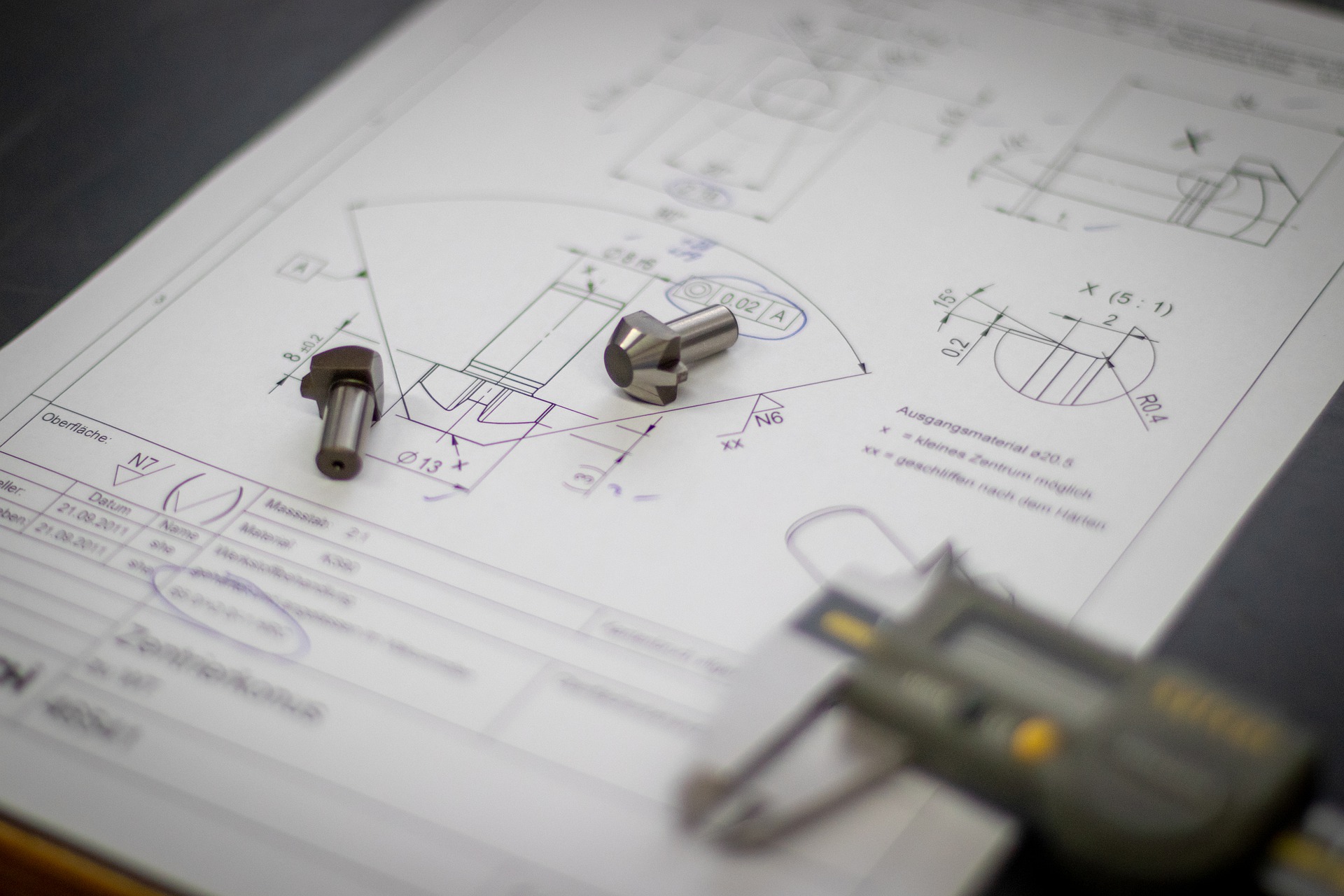

2D & 3D CAD engineering

In this phase we realize smart functional and constructive solutions. We thoroughly detail all parts to ensure that they meet the requirements and design criteria. To test these requirements we use 3D CAD modelling, calculations, FEM analysis, mold flow simulations, tolerance analysis and cost calculation. We also look at the selection of suitable technologies, materials and components. Integration of electronics and mechanical solutions is also taking place now. During this phase it is important to collaborate with manufacturers, suppliers, development partners and other stakeholders.

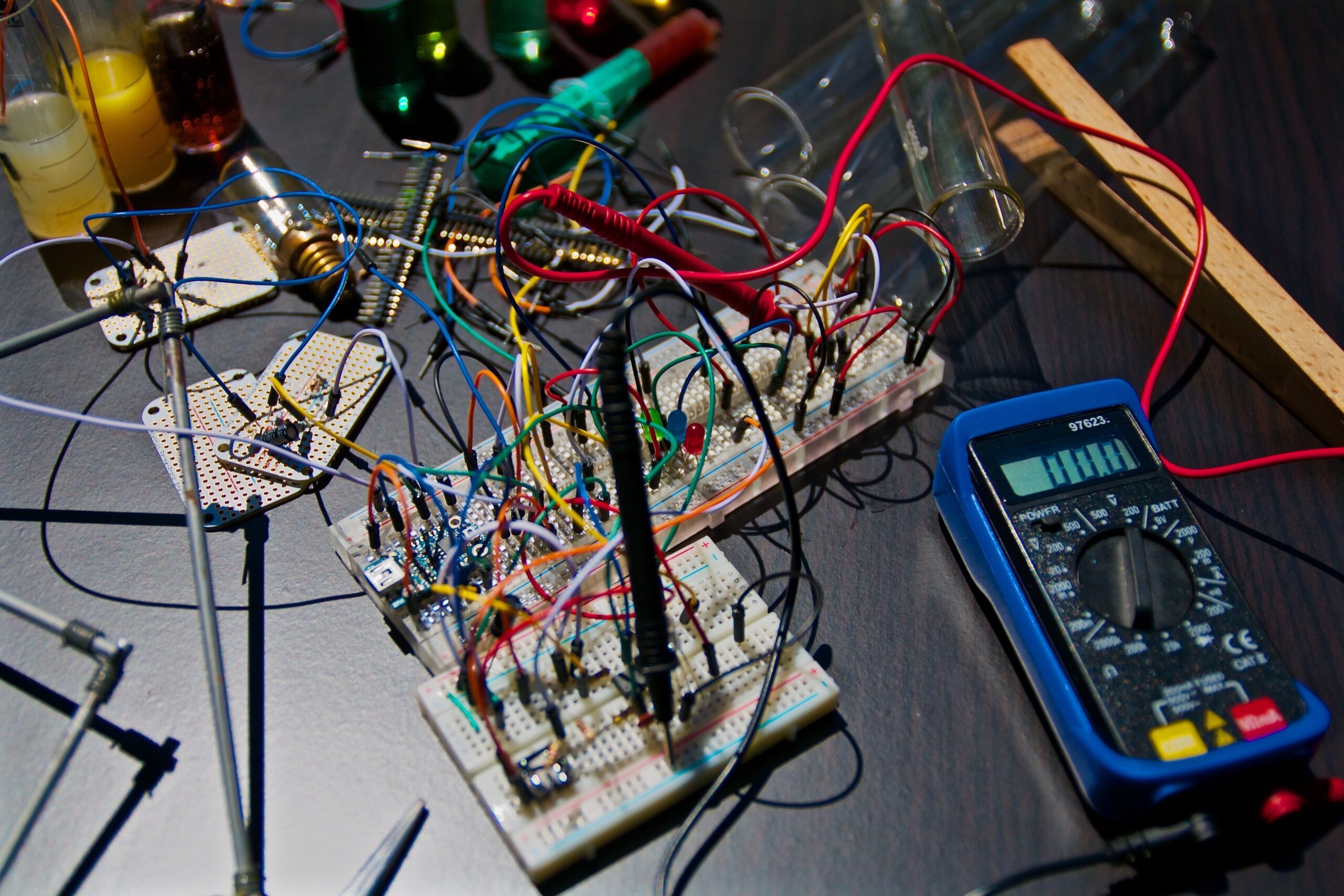

mechatronics engineering

When detailing the product, we also work on the integration of electronics that are essential for proper product functionality.

Processors, actuators and sensors are first being linked together in a lab environment. After that a program is being written to ensure that the electrical components work together correctly. At the same time, we test the functionality of this setup in order to see if we meet all the requirements and design criteria.

This way we create a working setup of electrical components that will be integrated into the product at the later stage.

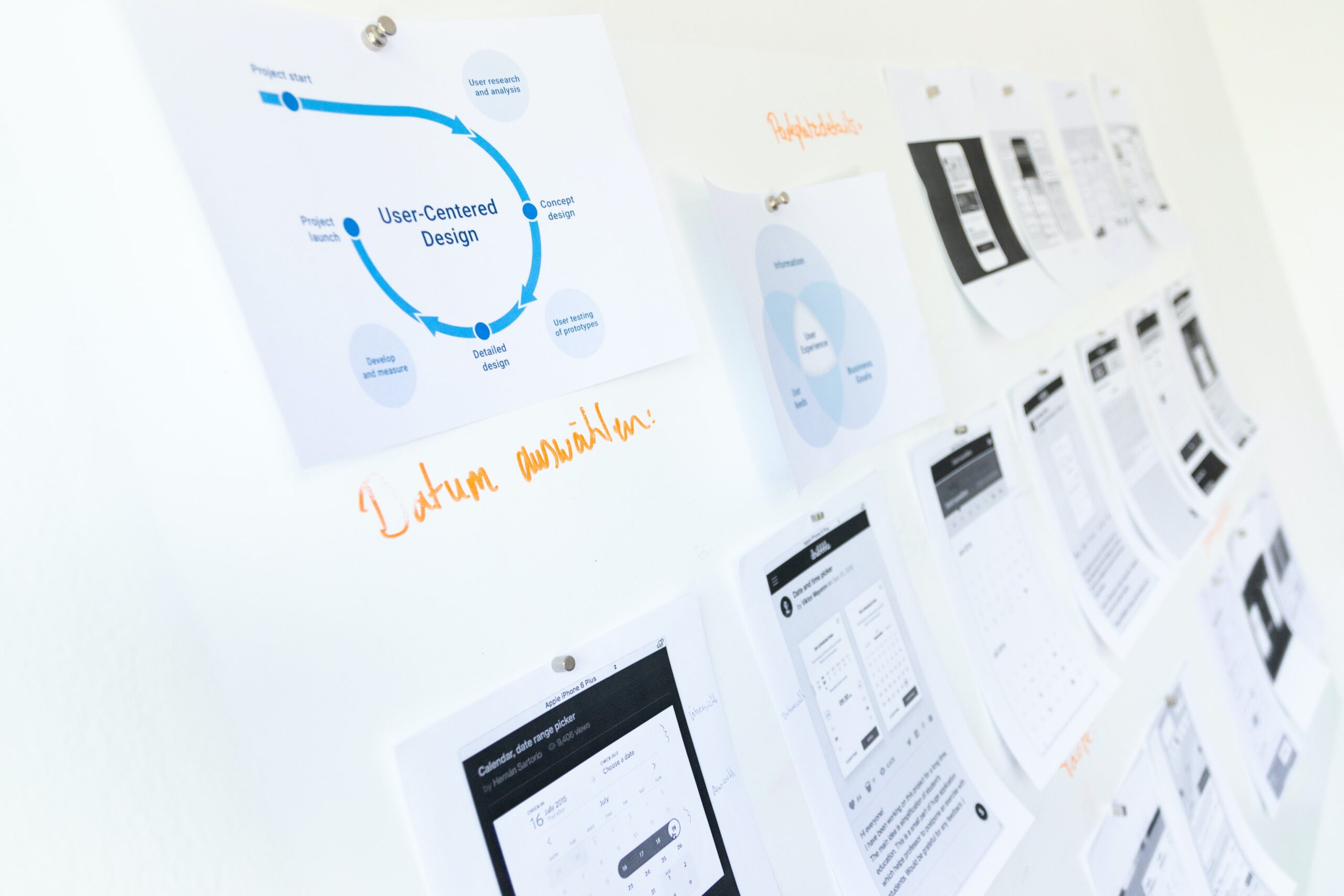

ux & ui design

Developing the interaction between user and product is an important step to provide users with easy user experience. It is important for us to allow potential users to test models, prototypes and interfaces during this design phase. At the same time, we observe the interaction behaviour of users and operating methods of different target groups. To obtain the research results, we often conduct surveys and interviews with the users and stakeholders.

Optimization, developing, testing and realization of suitable control solutions are continuously repeated in our design process in order to be able to apply all user requirements into the final product. Ensuring an efficient, safe and attractive interaction, both with the digital user interface and with the physical product, is important to stimulate optimal user and product experience.

service design

We add value to customers through their product related services to design and innovation. Think about installation processes manuals, maintenance manuals and the selection and use of relevant accessories. These services also determine how a user experiences a product interaction and therefore have a strong influence on the ultimate customer satisfaction.

We use a human-centered approach and use interviews, persona, context mapping or making flow charts. We also conduct research to understand cognitive ergonomics and the understanding of the user. This way we are able to devise and optimize the entire product service system. Now that we are also develop the product services, we are able to create complete end-to-end solutions.

prototyping & testing

Making prototypes is one of the essentials that we do in our design processes. By creating models with our 3D printer or by using our workshop we can generate a lot of tangible solutions that will be collected, selected and tested as potential concepts for the future prototype(s).

We prototype the models in order for them to be reviewed tested and verified. From simple foam model to one by one concept that can be presented to judge and discuss its look and feel. From integrating of all electronics inside a mock-up in order to make it look like a real operating prototype to testing assembly, look and feel and materials. Converting ideas into actual concepts helps to understand the future product and make necessary changes before the product is put into production.

realisation & implementation

When the ideas have been converted into concepts and from all the concepts the few were chosen, it is time to create a life looking prototype that will meet all the design criteria.

In this phase we focus on developing design specifications that are necessary for manufacturing. By doing this we are sourcing the needed materials, components and suppliers that can help with the future production. Meanwhile we work together with the client and stakeholders in order for the prototype to meet its last fine tune steps.

At the end of the project we deliver all the documentation and reports regarding design research and the included 3D CAD models, prototypes and technical drawings.

Your Product Built By Our Services

All design plans include the following client oriented features that are essential for the proper course within design process.

Professional Approach

We build valuable relationships with our clients in order to provide them with the best service in the future.

Regular Chat

As our customer you are free to contact us at any moment to discuss any unexpected changes in your design and new ideas.

Vast Review Moments

We make regular review moments where you can update us about any significant changes in your design.

Flexible Work Ethic

We strive to work efficiently and flexible in more than fifteen design disciplines. This allows us to keep an eye on all projects at the same time.

Wishes & Demands

Our main goal is to keep our customers satisfied with the work that meets their requirements and wishes.

Grow Strategy

While working on your design we develop the grow strategy that can be used in the product that we deliver at the end of the project.